Understanding the Role of an Optical Fibre Diameter Analyser in Optical Communications

Understanding the Role of an Optical Fibre Diameter Analyser in Optical Communications

Blog Article

How an Optical Fibre Diameter Analyser Enhances Top Quality Control in Fibre Production

The combination of an Optical Fibre Diameter Analyser into Fibre production procedures represents a significant improvement in top quality control approaches. By supplying real-time, accurate measurements of Fibre sizes, this technology deals with the essential need for consistency in manufacturing requirements.

Relevance of Fibre Diameter Dimension

Exact dimension of Fibre Diameter is important in the field of optical Fibre innovation, as it directly influences the performance and reliability of Fibre optic systems. The Diameter of an optical Fibre impacts its light-carrying capability, attenuation, and overall transmission efficiency. Accuracy in gauging Fibre Diameter guarantees that the optical residential properties are preserved within specified tolerances, which is vital for optimum signal honesty.

Variants in Fibre Diameter can bring about raised losses as a result of scattering and modal dispersion, impacting the top quality of information transmission. In high-speed communication systems, such discrepancies can cause substantial deterioration of signal quality, leading to information errors and reduced efficiency. Constant Fibre Diameter is important for compatibility with adapters and splicing innovations, which are essential components of Fibre optic networks.

Quality assurance processes in Fibre production greatly rely upon accurate Diameter dimensions to make sure compliance with market standards. By carrying out robust dimension techniques, makers can enhance item reliability, lessen waste, and improve total system performance. Therefore, the importance of Fibre Diameter measurement can not be overstated, as it functions as a keystone in the improvement of optical Fibre innovation and its applications in modern-day interaction networks.

How the Analyser Functions

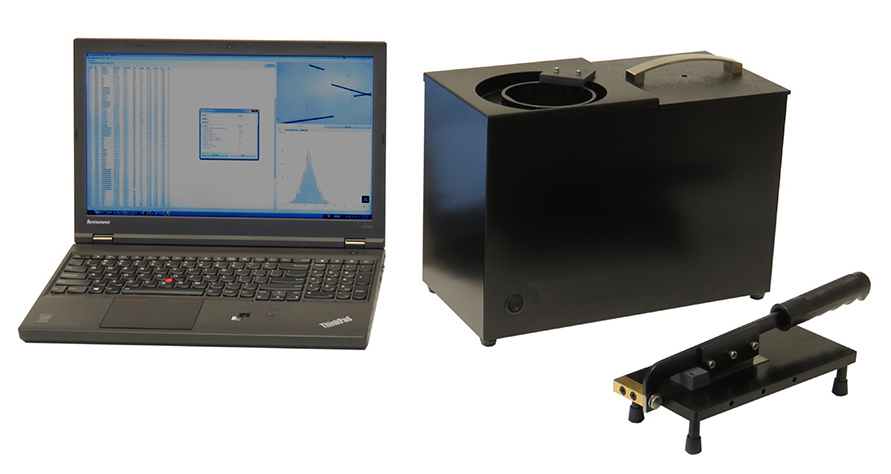

The effective measurement of Fibre Diameter counts on innovative analytical methods that ensure precision and integrity in optical Fibre production (optical fibre diameter analyser). The Optical Fibre Diameter Analyser uses a combination of laser innovation and progressed photo processing algorithms to precisely analyze the Diameter of fibres as they are created

Originally, a laser beam is directed at the moving Fibre, developing a cross-sectional darkness. The analyser captures this shadow utilizing high-resolution electronic cameras placed strategically along the assembly line. The caught photos are after that refined in real-time to determine the Fibre's Diameter with phenomenal accuracy.

The system uses sophisticated algorithms that account for various elements, consisting of variants in light strength and environmental conditions, to enhance measurement reliability. It can discover minute modifications in Diameter, such as fluctuations that may happen during the manufacturing process.

In addition, the analyser is qualified of taking care of numerous fibres concurrently, boosting throughput without jeopardizing accuracy. By offering immediate comments on the Diameter, the Optical Fibre Diameter Analyser plays a crucial duty in preserving strict high quality control requirements, guaranteeing that the final item satisfies industry requirements and client requirements.

Advantages of Real-Time Tracking

While standard approaches of keeping an eye on Fibre Diameter commonly involve taxing post-production checks, real-time tracking considerably enhances the performance and quality of optical Fibre manufacturing. optical fibre diameter analyser. This aggressive technique allows makers to identify inconsistencies in Fibre Diameter as they occur, instead of waiting until manufacturing is complete to examine quality

By continually measuring the Diameter throughout production, suppliers can guarantee that the fibers meet rigid specifications, causing reduced irregularity and boosted consistency. Real-time tracking additionally allows prompt corrective actions to be taken, decreasing waste and avoiding faulty fibers from entering the supply chain.

Moreover, this modern technology helps with improved information collection and analysis, offering understandings right into manufacturing trends and prospective locations for renovation. Such data-driven decision-making encourages manufacturers to enhance procedures and keep high standards of quality assurance.

Furthermore, real-time tracking promotes a culture of continuous enhancement within the manufacturing setting. Employees are a lot more involved when they can see have a peek at these guys the impact of their operate in real-time, resulting in increased liability and a dedication to quality. On the whole, the implementation of real-time monitoring systems in optical Fibre manufacturing translates to superior product quality and increased customer fulfillment.

Effect On Production Effectiveness

Executing optical Fibre Diameter analysers substantially improves production efficiency by streamlining the manufacturing procedure. These tools assist in constant tracking of Fibre Diameter, permitting makers to identify inconsistencies in real-time. By recognizing incongruities without delay, assembly line can be changed rapidly, minimizing downtime and reducing the likelihood of generating malfunctioning products.

In addition, the combination of these analysers into the manufacturing process allows better source allotment. With accurate Diameter measurements, drivers can enhance material use, making sure that resources are not thrown away on problematic fibres. This accuracy likewise adds to much less rework and junk, eventually lowering manufacturing expenses.

The automation offered by optical Fibre Diameter analysers reduces dependence on manual examinations, which are commonly time-consuming and vulnerable to human special info mistake. Consequently, staff members can focus on even more tactical jobs, enhancing general performance.

Furthermore, the information generated from these analysers can notify procedure enhancements and facilitate much better decision-making. By assessing trends in Fibre Diameter variants, suppliers can execute positive measures to improve manufacturing strategies and preserve constant top quality. In summary, optical Fibre Diameter analysers play a crucial function in enhancing production effectiveness, causing greater quality outcome and raised profitability.

Situation Researches and Success Stories

Throughout various industries, study highlight the transformative influence of optical Fibre Diameter analysers on manufacturing processes. One popular example is a leading telecoms firm that encountered obstacles with irregular Fibre sizes, leading to increased rejection rates. By incorporating an optical Fibre Diameter analyser, the business attained real-time surveillance of Fibre measurements, causing a 30% decrease in issues and substantial price financial savings.

Furthermore, a research study institution concentrating on advanced products utilized optical Fibre Diameter analysers to fine-tune their experimental procedures. The analyser's capability to supply detailed understandings into Fibre uniformity enabled the growth of innovative products with improved performance features.

These success stories emphasize the vital duty of optical Fibre Diameter analysers in boosting quality assurance, enhancing manufacturing efficiency, and driving advancement across diverse markets.

Verdict

To conclude, the Optical Fibre Diameter Analyser plays a pivotal function in boosting quality control within Fibre production. By supplying specific, real-time measurements and assisting in prompt rehabilitative actions, this innovation dramatically reduces variability and lessens waste. The execution of such innovative devices fosters a culture of constant enhancement and functional performance, inevitably ensuring compliance with industry requirements and preserving competitiveness. As shown with different study, the analyser confirms essential for achieving exceptional product high quality in Fibre manufacturing.

The execution of optical Fibre Diameter analysers enabled for rigorous top quality control, guaranteeing that the generated fibres fulfilled exacting industry requirements.In conclusion, the Optical Fibre Diameter Analyser plays a pivotal function in enhancing high quality control within Fibre production.

Report this page